General FAQS

Q. How to place an order?

A. Once you have found the instrument that you require, simply select from the drop down box which option you would like and then click on the “Add to Cart’ button on the page. This will automatically add this to your cart. You can update your cart at any stage by clicking on the ‘My Cart’ button at the top of the page.

Once you have finished browsing, click on “Checkout’ which will take you through the process of finalizing your order and paying. You can pay by setting up an account/becoming a member – which will remember your details for future orders or as a guest.

Q. Do I have to set up an account to make a purchase?

A. No, you do not need to set up an account, however, setting up an account only takes a few minutes and will remember your details for future orders. Once you have set up an account, you will receive a username and password for you to sign in. This will allow you to easily access account information next time you log in. Once you register, you have access to your account instantly. The registration process is simple and will only ask for you standard questions including Surgery/Company name, contact person, address, phone and email address.

Q. Do you have any privacy statement?

A. When you provide contact or billing information by phone or Internet, that information is kept strictly confidential. We will not sell, share, or rent user information to any outside party not directly involved in the processing of your current transaction. All information transmitted by you to us while visiting our website is secured.

Q.Do you have any other Email Address?

A.No Only sales@asn-instruments.com is valid email for customer.Any information you need you will asked us by sending email from your valid email address.We will not provide any information on phone or any other mode.We are not responsible for any damage caused by third party.All sales dealing will be done through sales@asn-instruments.com.As long as you haven’t received confirmation email from Sales@asn-instruments.com please do not make any deal.

Q. I would like to distribute Asn Instruments product in my country, what do I have to do?

A. We are now looking for new distributors from all around the world. If you are interested in becoming a distributor, please complete our online-form or please call or email at sales@asn-instruments.com with your location information and business details. We will reply you within a few days.

Q. Does Asn Instruments modify instruments or make custom-designed instruments? I have some great

ideas for developing a new products?

A.Surgical Instrument Modifications: Yes, modifications to existing surgical instruments are quite common and in most cases can be performed by our expert repair facility. Please call or email at sales@asn-instruments.com

Custom Surgical Instruments: We have an expert engineering staff at our factory who can discuss and help design custom instruments and everything involved in producing exactly what you need. Please call or email at sales@asn-instruments.com to discuss Quality FAQS

Q. Is your company ISO certified?

A. Yes, we are An ISO 9001:2000 and ISO 13485 Certified Company. We have FDA Registrations, and CE Marking for many of our products.

Q. Are asn-instruments traceable?

A. All our featured instruments are laser marked with necessary information for complete traceability. Instruments are marked with our company logo, CE, product code with lot number indicated on the product packaging.

Q. How does Asn-instruments inspect their instruments?

A. All items leaving Asn-instruments facility are meticulously inspected as per our standard guidelines, which exceed international ISO standards. During the manufacturing process, each item is subjected to constant functional and visual checks by master craftsmen using the latest tools and optical technologies to ensure our standards are met.

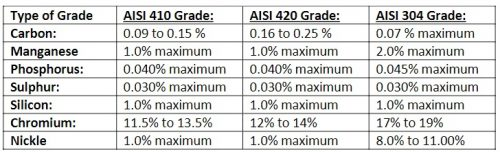

Q. Which types of stainless steel are used in manufacture of Asn Surgical Instruments?

A. The stainless steels used in the manufacture of Asn Surgical instruments can be divided into two main classes.

1. Austenitic (Non-magnetic)

2. Martenitic (Magnetic)

Non-magnetic stainless: Non-magnetic stainless is used in the manufacture of instrument where hardness is not important. It contains less carbon steel and so is less susceptible to corrosion and staining. Grade 304 sheet metal are used in the manufacture of all instruments in this category.

Magnetic stainless: Magnetic stainless is used for the majority of all other instrument manufacture. These can be hardened by heat treatment to give strength and durability to the instrument. Magnetic grade steel contains more carbon and therefore is more susceptible to corrosion and staining if careful adherence to percentage composition is not followed. Grade 410 and 420 rod are used in the manufacture of all instruments in his category.

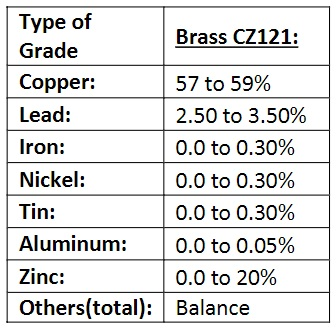

Q. What other material you are using apart from Stainless Steel?

A. Other Materials we are using in manufacturing Surgical Instrument is Brass Grade CZ121.Mostly we are using brass material in items like Aspirating Syringes and similar items.

Q. Tell me about the specification of steel you are used?

A. Specification of steels are as follows:

A. Specification of Brass are as follows:

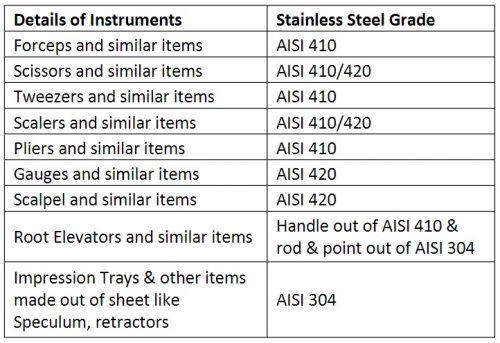

Q. Tell me about the detail of instruments used out of stainless steel of different grades?

A. Details of the raw materials (stainless steel) normally being used are as under

MANUFACTURING PROCESS AT Asn-instruments FAQS

MANUFACTURING PROCESS AT Asn-instruments FAQS

Q.Tell me about production process of Asn-instruments?

A.Following is the production process of Asn-instruments

1. MATERIAL USED: Always a best quality stainless steel material is purchased from steel manufacturers. Two kinds of series i.e. 304, 410 and 420 of stainless steel and Brass CZ121 is used for

production of Surgical Instruments.

2. MATERIAL TESTING: The purchased raw material is thoroughly tested under PQA. Authority. A rigid quality control policy is being adopted before releasing to production. This test is taken to check the standard of steel as per desired specifications and is considered the most important factor of our business.

3.FORGING & HAMMERING: After testing, the stainless steel strips/bars are divided into different sizes as per our requirements and our highly experienced craftsmen are specialized in forging (Hot/Cold Drop)

to perform all standard press operations in forming and deep drawing of all type of instruments. We anneal the forging and prepare for the milling process.

4. MACHINE & TOOL WORK: Our highly skilled technicians have a great knowledge about machine milling process. We form accurately male/female portion of box-joint forceps, as well as,

serrations/ratches in uniformity. We are equipped to mill, drill, bore turn and grind all type of metals.We have in house facility of custom tool and die production, maintenance and repair.

5. FILLING: We are specialized in hand–made fabrication. First, we assemble male/female portion after setting/adjusting of Extracting Forceps and Scissors, tips, serrations, ratches in uniformity and file precisely to make it semi-finish under strictly quality control specifications. We are now moving from basic hand manufacturing techniques to mechanization to production run.

6. HEAT TREATMENT: All instruments are being tempered maintaining “Rock-Well Hardness” for Hemostat/Forceps 40° to 45° degree, Extracting Forceps & Retractor 45º to 50º degree, Scalar, Gauges and Scalpel 50° to 55 º degrees, Scissors 45° to 55° degree. A test is taken to check the hardness after

tempering of each lot to maintain the uniformity and, before proceeding further, we clean all instruments by various chemicals. In addition, we will buy specialized Q/C equipment in near future to meet special customer Q/C. specifications.

7. RIVETING & WELDING: We perform a wide variety of assembly operations from prototype quantities to production run. We rivet precisely each instrument such as, Hemostat/Forceps and Scissors, Extracting Forceps & Retractor, etc. But, for some kind of instruments, we use spot welding.

8. GRINDING & POLISHING: For precise grinding and excellent finish, we specialize in applying polishing wheels to belts to improve the overall finish in high uniformity utilizing best of polishing luster. We use electro-plating plants to polish serrations/ratches and joints of stainless steel instruments. For satin/matt finish instruments, we use glass heads to achieve uniformity. All instruments are being polished under rigid quality control specifications.

9. PASSIVATION: This method actually provides the instruments with its corrosion resistance properties. Passivation, which follows the final polishing step, is a chemical bath, which creates an

oxidized layer on the surface of instruments. We are now equipped with most modern process.

10.ULTRASONIC CLEANING: We are full equipped with most modern ultrasonic cleaning plants imported from “Branson Cleaning Equipment Co. USA”, and all instruments are being cleaned properly

utilizing various chemicals such as, Tri-Chloroethlyine etc.

11. INSPECTION: We inspect all instruments under rigid Q/C. specifications and give the assurance to our relative clients that all instruments shall be free from all defects such as, burrs, sharp edges, cracks, pitting, scratches, grease / excessive oil and foreign matters etc. We also guarantee for its workmanship.

12. STAMPING: For stamping, we use both process i.e. die sunk and electrolytic marking and are being marked under customer’s specifications.

13. PACKING: We pack all instruments under strictly Q/C. specifications as per customer’s demand. Normally, we pack individually in polybag and further 12 pieces in one box mentioning outside with Part Number, Description and Lot Number. All instruments are packed in polybags with adequate desiccant in each polybag to absorb moisture.

14. LABELING: Mostly, we are packaging and labeling as per customer demand.

Instrument Care and Maintenance FAQS

Q.Tell me the solution to instrument care and maintenance?

A.Remember, there are four simple step for solution to instrument care and maintenance:

1. Cleaning

2. Lubrication

3. Inspection

4. Sterilization

1. CLEANING

Q. How should I clean my instruments?

A.This depends on how sterile your protocol requires them to be. First rinse the in pH neutral distilled water and remove any blood and/or debris. Use a fresh neutral pH solvent and then a soft brush for the tough cleaning. If you steam autoclave make sure that you use the manufacturers for your autoclave (clean neutral pH distilled water), and that your high quality instruments are not mixed with instruments of inferior quality. Impurities from the lower quality instrument can start a corrosive action on your higher quality ones. Be sure that a full drying cycle is used. Overlapping joints may have dampness within the joint, increasing the chance of corrosion. This can be prevented in three ways; assure the full drying cycle is complete, apply silicone grease inside the joint as a protective layer, or by use of an air canister or hair dryer to blow moisture out of overlapping parts. Instruments can also be cleaned ultrasonically but must be immediately rinsed and dried.

Q. Can I clean my instruments manually?

A. Asn Surgical Instruments recommends using ultrasonic cleaning (Sentry Ultrasonic Cleaner) as the best and most effective way to clean surgical instruments. If ultrasonic cleaning is not available, instruments may be cleaned manually using a pH neutral detergent, distilled water, and a soft instrument cleaning brush.

Q. Can I use a bleach solution to clean my instruments?

A.Never use bleach to clean any surgical instruments. The high pH of bleach causes surface deposits of brown stains and might even corrode the instrument. Even high quality stainless steel is not impervious to an acidic bleach solution.

Q.Which is the best method for cleaning instruments, manual (brush) or automated (ultrasonic)?

A .Debris can be removed from an instrument either by scrubbing the instrument manually with a surfactant or detergent and water or by using automated equipment (e.g., ultrasonic cleaner, washer-disinfector) and chemical agents. After cleaning, instruments should be rinsed with water to remove chemical or detergent residue. Splashing should be minimized during rinsing and cleaning. Considerations in selecting cleaning methods and equipment include their effectiveness, their compatibility with the items to be cleaned, and the occupational health and exposure risks they pose. Because instruments cleaned with automated cleaning equipment do not need to be presoaked or scrubbed, the use of automated equipment can increase productivity, improve cleaning effectiveness, and decrease worker exposure to blood and body fluids. Thus, using automated equipment can be more efficient and safer than manually cleaning contaminated instruments.

Q. How do I perform ultrasonic cleaning?

A.Using ultrasound combined with a special cleaning solution, it is the most effective cleaning method available. Recommended for regular instruments such as hand instruments and forceps.

Advantages:

•Safer than hand scrubbing.

•Cleans instruments and very effectively.

•Reduces the risk of contaminants spreading through splatter.

•Allows for more efficient use of staff time.

Steps to follow:

1.Sort instruments carefully so as to include only instruments compatible with ultrasonic cleaning

2.Make certain sharp edges are not touching other instruments

3.Do not combine different metals (chrome plated, stainless, copper, titanium, etc.).

4.Change the solution frequently to avoid accumulation of microorganisms.

5.After rinsing and before sterilization, inspect and dry the instruments thoroughly.

Remember: Ultrasonic cleaning is not recommended for instruments which are very delicate, which have sharp cutting edges (scissors, needle holders , bone forceps) and not 100% steel (rubber, mouth mirrors, titanium, TC-tungsten carbide inserts or diamond dusted tips, etc.). The ultrasonic vibrations can chip, break or corrode any welded parts. For the delicate instruments, use manual cleaning.

Q. My scissors are becoming stiff and hard to use, how do I improve their action?

A.We recommend first cleaning the instruments in a neutral pH detergent solution with distilled water. Then apply a surgical instrument lubricant – following the manufacturer’s instructions.

2. LUBRICATION

Q. Why you should lubricate surgical instruments?

A. Lubrication is the most important action you can take to extend the life of your instruments. The use of a surgical instrument lubricant will prevent spotting from mineral deposits left behind by water after cleaning. Corrosion can also be prevented by the application of lubricant. Corrosion starts in the pores of the metal and is often related to improper cleaning. With proper handling and lubrication the surface of your stainless steel instruments will develop a thin hard coating, similar to oxidation, which will help prevent damage from corrosion. Known as the passivation layer, it makes the instruments more resistant to staining and rusting. In addition to stain and corrosion protection lubrication reduces friction at the joints, keeping the action of the instrument light, delicate and smooth – extending the life of the instrument by reducing wear.

3. INSPECTION

Q.How to inspect surgical instruments?

A .The importance of inspecting each instrument cannot be over emphasised. Each surgical instrument is designed for a specific purpose. Inspection has to be carried out to ensure that they still function as they should. If in any doubt, the manufacturer should be contacted to advice on suitable inspection methods. Fine and delicate instruments should be inspected under an illuminated microscope. In order to avoid damage during handling at this stage place the instruments on specially designed racks and holders to prevent them knocking together, especially the tips of sharp instruments. All hinged instruments such as clamps and forceps should be checked for stiffness and to ensure the joints work smoothly. The tips of instruments should be of equal length, jaws close evenly, approximate initially at the tips and be fully approximated when closed to the last ratchet. There should be no excess play in any box joints and the ratchets should operate smoothly, hold firmly, even when knocked, and open easily. The edges of sharp and semi sharp instruments such as scissors, ronguers, chisels, curettes etc. should be inspected for sharpness. Scissors should close smoothly with no ‘grinding’ around the pivot pin. There should also be no dull spots, chips or dents in the cutting edges.

Plated instruments must be checked for chips, as this would harbor debris, and also for sharp edges and worn spots. Sharp edges will damage tissue, surgeon’s gloves and worn spots may be susceptible to rusting and corrosion during sterilization. All instruments with pins and screws should be carefully checked to make sure they are completely intact and safely located.

General Guide on How to Inspect Instruments Forceps and Hemostats: A visual test would be to close the jaws lightly. If they overlap they are out of alignment and need re-aligning. If the forceps have serrated jaws they should be checked to see that they mesh fully. There should be no play in the box joint of the instrument. The ratchet should be closed and the instrument held by the box and tapped lightly on the other hand. If the ratchet springs open it is faulty and in need of repair. (This would not be ideal if the haemostat were on a vessel and sprung off

when knocked by a hand or other instrument!)

Scissors: The standard test for all operating scissors should be applied. All Mayo and Metzenbaum type scissors should cut four layers of gauze at the tip of the blade. Smaller scissors of less than 10cm in length should cut two layers in the same way. Blades should be checked for burs and they should be in good approximation all the way down the length. There should not be excessive fretting around the pivot pin which would lead to possible corrosion and breakage.

Needle Holders: A needle should be clamped in the jaw and the instrument closed to the second

ratchet. If the needle can be moved or turned easily then the instrument needs repairing.

4. STERILIZATION

Q. What is sterilization?

A. It is a procedure which removes all pathogenic and non-pathogenic micro-organisms; it should be

performed with outmost care. These are the most common and effective sterilization techniques:

• Autoclave (steam sterilization)

• Chemiclave (chemical sterilization)

• Dry heat sterilization (not recommended)

Remember: Ultrasonic cleaning does not sterilize.

Q. How do I perform steam sterilization (autoclave)?

A. Steam autoclave (moist heat) sterilization using a pre-vacuum (forced air removal) cycle is recommended. Instruments are treated with high pressure water steam.

Minimum and maximum recommended standards for Steam Sterilization / Autoclave:

Time: 5-15 minutes Temperature: 132°C (270°F) – 135°C (275°F) Sterilizing agent: distilled water.

Advantages:

•Highly effective.

•Nontoxic.

•Inexpensive.

•Rapid heating.

•Rapid penetration of instruments.

Disadvantages:

•Items must be heat and moisture resistant.

•Needs good maintenance (The autoclave is not working correctly if steam comes out of the lid or around the door).

Q. How do I perform chemical sterilization (Chemiclave)?

A. Instruments are treated with high pressure, with the help of chemical steams. Instruments must be dried before sterilization.

Minimum and maximum recommended standards for Chemical Sterilization / Chemiclave:

Time: 5-15 minutes Temperature: 132°C (270°F) – 135°C (275°F) Sterilizing agent: special chemical solutions..

Advantages:

•Minimal dulling, rusting and corroding of instruments.

•Unsaturated chemical vapor method is a low-humidity process.

•The heat-up time is shorter than for most steam sterilizers.

•Easy to operate, fill and purge / Minimal order.

Disadvantages:

•Needs adequate ventilation / It is flammable.

•Vapo-Steril solution has formaldehyde in it, known to be a potential carcinogen.

•Needs to be mixed with water when disposed.

Q. How do I perform dry heat sterilization?

A.Instruments sterilization takes place by means of hot air. Instruments must be dried before sterilization. At present, this sterilization technique is not recommended, as it does not guarantee

reliable sterilization and gradually causes damages.

Minimum and maximum recommended standards for Dry Heat Sterilization:

Time: 60 – 90 minutes Temperature: 160ºC (320ºF) – 170º C (340ºF)

Advantages:

•Reaches surfaces of instruments that cannot be disassembled. This is accomplished by conduction.

•Low cost.

Disadvantages:

•Long exposure time is necessary.

•V High temperatures gradually cause damages such as surface blackening, loss of polish and dullness.

•Specialized packaging is needed.

Q. How to properly store surgical instruments?

A.When storing or handling surgical instruments it is recommended that they are never stacked or piled together. This may cause physical or other damage to instruments, including the larger ones. Instrument edges, points and finish are best protected by individually laying them in a storage container. It is important that this area be a dry drawer or cabinet. The use of drying agents such as silica packets or even an open box of baking powder will aid in controlling moisture. When storing instruments re-using tip guards may reduce damage to instrument tips. However, do not autoclave an instrument with the tip guard on. The tip guard might retain moisture that could cause staining or the tip may not be sufficiently sterilized.

Q. How does corrosion and pitting occur and how to prevent it?

A. Following are reasons for corrosion and pitting:

Corrosion Presence of blood and soil in box locks, ratchets, serrations, hinges etc. can cause corrosion. More care should be taken in cleaning. Excessive moisture left on the surface of the instrument can lead to corrosion. Preheat the autoclave, do not rush the drying time. Foreign matters deposited in the autoclave can result in spotting and corrosion of instruments. Inner surfaces of the autoclave should be given a routine maintenance. Wipe down with acetic acid (equal parts of vinegar and distilled water) to remove any impurities. Stress corrosion can be caused by not opening box locks during sterilization procedure. The heating-up and cooling-down process during sterilization causes tension in the material.

Pitting When instruments are exposed to saline solutions, blood, iodine, potassium chloride and other compounds pitting will occur. Instruments should be rinsed thoroughly immediately after exposure. Pitting can also be traced to detergents with a high pH level (B-9) used for instrument cleaning. Instruments should be thoroughly rinsed after cleaning. It is impossible to completely restore an instrument after pitting or rust has eroded the hard surface. The instrument should be replaced immediately as a pitted instrument is far more susceptible to further corrosion.

Q. How to diagnose spots and stains?

A.It is common for instruments to become stained or spotted despite the best efforts. In nearly all cases these problems are the result of minerals deposited upon the surfaces of the instruments, as well as insufficient cleaning. Proper technique during cleaning and sterilizing procedures will prevent most staining occurrences. The following identifies some of the various instrument-related may encounter:

• Brown/Orange Stains: A result of high-pH detergents. Chlorhexidine usage or improper soaking of instruments. This color stain can also be caused by soaking in tap water.

• Dark Brown Stains: Low-pH instrument solutions. The brownish colored film may also be caused be a malfunctioning sterilizer. Similar localized stain spots can also be a result of baked-on blood.

• Bluish Black Stains: Reverse plating, when instruments of different metal (e.g. chrome and stainless steel) are ultrasonically processed together. This can occur when high quality instruments are mixed with lower end ones. Additionally, exposure to saline, blood, or potassium chloride will cause this bluish black color. (Similar to tarnish on silverware).

• Black Stains: Contact with ammonia or a solution containing ammonia.

• Light or Dark Spots: Water droplets drying on the instruments. With slow evaporation, the minerals sodium, calcium and magnesium left behind can cause this spotting.

• Rust Deposits: Dried blood that has become baked on the serrated or hinged areas of surgical instruments. This organic material, once baked on, may appear dark in color. Also can be caused by soaking in tap water.

Q. How to remove stains?

A.Stains can be removed, whereas rust will leave permanent damage. To determine if a brown or orange discoloration is a stain or rust, use the eraser test:

• Rub a pencil eraser over the discoloration.

• It the discoloration is removed with the eraser and the metal underneath is smooth and clean, this is a stain.

• If a pit mark appears under the discoloration, this is corrosion or rust.

Q. In case I still have any queries, what should I do?

A. Feel free to forward your questions to us through our 24-hour functional customer support center